The most commonly used 3D technologies for digital output include 3D printing, CNC milling, and laser cutting. All of these machines work with CAD drawings created using software applications like Rhino. This capstone project for the course seeks to provide students an opportunity to get acquainted with these processes while producing models for their final design in studio. Special attention is paid to a good setup in CAD that enables efficient iteration through designs, and to investigate ways of exerting more control in the process to obtain more creative results. Just as the practice of descriptive geometry has been radically transformed by computational techniques in the past few decades, so this transition into the information age has impacted the domains of manufacturing and fabrication. The dominant paradigm of mass production has begun to be displaced, as artisanry was before it, and replaced by a much tighter loop connecting design prototypes, design specifications, manufacturing process models, and machine instructions.

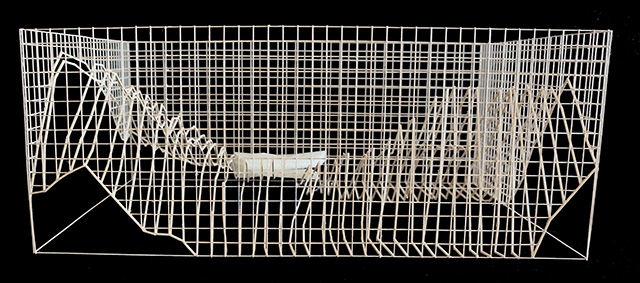

Using a combination of fabrication processes and machines, including CNC milling, laser cutting, and 3d printing, students produce a large-scale model constructed of materials of their choosing. The model serves as a site and scheme model for their final design project, depicting the overall form of the proposed scheme and how it relates to site conditions, including a proposal for built intervention and modifications to existing topography and site.

This capstone project introduces three fabrication devices - the CNC mill, the 3d printer, and the laser cutter - and culminates in the fabrication of a site and scheme model employing all three in some combination. Of these, the CNC mill presents the most challenges, as it is both the most time-intensive and requires more planning and forethought in comparison to 3d printing and laser-cutting.

Acquiring expertise on the CNC mill will proceed through two basic stages.

Working in groups, students research an assigned material and milling process, produce a test cut object employing that process, and prepare a presentation on the results.

Following the group investigations, and applying the knowledge gained from the collective efforts of the class, each student prepares a proposal for a model fabrication method that involves not only the CNC mill, but all three fabrication machines.

The final model, produced at 1/16" = 1', will serves both as a representation of site and as the basis for a representation of the proposed scheme in studio. Stemming from preliminary site mappings, the site may contain both concrete and abstract elements, but must express some response to the following:

There's more!

Some other projects from this same class have been posted, as well as some interesting student work from this same year.